Conectores de liga de alumínio fundido: os heróis anônimos que moldam a estabilidade dos móveis modernos

2025-07-31 15:32

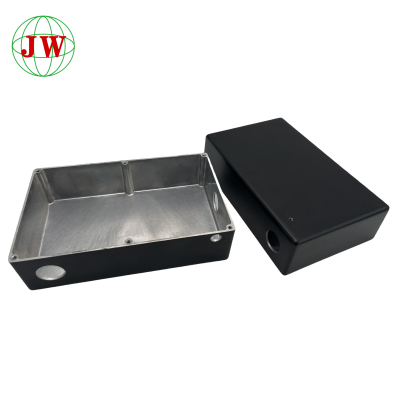

In the realm of furniture manufacturing, where aesthetics often take center stage, aluminum alloy die-cast connectors have emerged as silent workhorses, revolutionizing how furniture pieces are assembled, stabilized, and sustained. These small yet critical components, produced through precision aluminum die-casting processes and reliant on advanced molds, are redefining durability and design flexibility in the industry.

The Role of Aluminum Alloy Die-Cast Connectors in Furniture

Aluminum alloy die-cast connectors serve as the backbone of modern furniture, linking frames, legs, panels, and joints with unmatched precision. Unlike traditional wooden dowels, plastic clips, or welded steel parts, these connectors leverage the unique properties of aluminum alloys—lightweight, corrosion-resistant, and high-strength—to ensure furniture withstands daily wear, weight, and environmental stress.

In modular furniture, for example, die-cast connectors enable quick, tool-free assembly. A single connector might join a sofa’s armrest to its frame or lock a bookshelf’s adjustable shelves in place, supporting up to 50kg of weight without loosening. Luxury brands like IKEA and Herman Miller now specify aluminum die-cast connectorsin their high-end lines, citing their ability to maintain tight tolerances (as low as ±0.02mm) over years of use—preventing the creaks and wobbles common with cheaper alternatives.

Why Aluminum Die-Casting Stands Out for Connectors

The aluminum die-casting process is pivotal to the performance of these connectors. By injecting molten aluminum alloy (typically ADC12 or A380, chosen for their fluidity and strength) into custom molds under high pressure (1,000–15,000 psi), manufacturers produce connectors with:

Complex Geometries: Molds can shape connectors with internal threads, hollow cores, or interlocking teeth—features impossible to achieve with machining or forging. This allows designers to create sleek, hidden connectors that don’t disrupt a furniture’s visual appeal.

Uniform Strength: The die-casting process eliminates porosity and ensures even material distribution, giving aluminum connectors tensile strength up to 280 MPa—stronger than most plastics and comparable to mild steel, but at half the weight.

Cost Efficiency: High-volume production of connectors is feasible thanks to molds that can produce 100,000+ parts before requiring maintenance. This drives down per-unit costs, making aluminum die-cast connectors accessible for both luxury and budget furniture lines.

Molds: The Precision Tools Behind Reliable Connectors

The quality of aluminum die-cast connectors hinges entirely on the molds used to create them. Crafted from hardened H13 steel, these molds undergo rigorous machining and heat treatment to withstand the extreme temperatures (650–700°C) and pressures of die-casting.

Modern mold design, powered by 3D modeling and computer-aided engineering (CAE), optimizes flow paths for molten aluminum, ensuring every nook of a connector—from a tiny locking pin to a threaded bore—is filled perfectly. For example, a mold for a chair leg connector might include micro-channels to reduce air entrapment, preventing weak spots that could lead to breakage.

Mold makers also prioritize interchangeability. A single mold base can accommodate different inserts, allowing manufacturers to produce variations of a connector (e.g., longer/shorter threads) without redesigning the entire tool. This flexibility is key for furniture brands offering customizable pieces.

Advantages Over Traditional Connectors

Compared to alternatives, aluminum alloy die-cast connectors offer clear benefits:

Corrosion Resistance: Unlike steel, aluminum forms a natural oxide layer, making connectors ideal for humid environments (e.g., outdoor patios, bathrooms). Testing by the Furniture Industry Research Association (FIRA) showed aluminum die-cast connectors in outdoor furniture resisted rust for 10+ years, while steel connectors corroded within 2–3 years.

Eco-Friendliness: Aluminum is 100% recyclable, and many manufacturers use recycled alloy in die-casting. This aligns with the industry’s shift toward sustainability—consumers are 30% more likely to purchase furniture labeled “recyclable” in surveys by the Sustainable Furnishings Council.

Design Freedom: Aluminum die-cast connectors can be finished with powder coating, anodizing, or plating, matching any color or texture. This allows them to blend seamlessly with wooden, glass, or metal furniture surfaces, enhancing aesthetics rather than detracting from them.

Market Growth and Future Innovations

Demand for aluminum die-cast connectors is surging, driven by the rise of modular and smart furniture. The global furniture connectors market, valued at $4.2 billion in 2023, is projected to grow 6.8% annually through 2030, with aluminum die-cast variants accounting for the fastest growth segment.

Innovations in mold technology are fueling this expansion. 3D-printed mold inserts now enable rapid prototyping, letting designers test new connector designs in days instead of weeks. Smart molds equipped with sensors also monitor pressure and temperature in real time, reducing defects and ensuring consistent quality.

Looking ahead, alloy advancements—such as adding scandium to boost strength—will enable even smaller, lighter connectors without sacrificing durability. This will be critical for next-gen furniture, including foldable, space-saving designs and IoT-integrated pieces (e.g., sofas with built-in charging ports, where compact connectors free up space for electronics).

Conclusion

Aluminum alloy die-cast connectors may be small, but their impact on furniture manufacturing is immense. By combining the strength of aluminum alloys, the precision of die-casting, and the versatility of advanced molds, they deliver stability, sustainability, and design freedom. As furniture evolves to meet demands for durability, customization, and eco-consciousness, these unsung components will remain essential—proving that the strongest furniture is built from the best connections

Obter o preço mais recente? Responderemos o mais breve possível (dentro de 12 horas)